Amazon Replenishment & Cost Optimization

We provide stock recommendations to make sure that you get accurate and economic inbound quantity recommendations for your products at amazon warehouses. We help you to know what, where, when and how much to stock at amazon and maintain healthy inventory at the fulfilment centers.

Cost saving

Save upto 20% logistics cost with our advance planning and 30% storage cost by sending only the required quantity

Avoid loss of profit

Reduce stock out situations by 90%.

Time saving

Time taken from inputs to output in 6 hours

Deciding replenishment frequency

Frequent shipments to amazon can be costly. Depending on the available stock limits and available Inventory, you can either do frequent SPD shipments or one large LTL/ FTL shipment.

One LTL and less shipments also lead to saving in time:

- One LTL reduces your time to replenish the stock every week- creating labels,

- coordinating with the transporters to ship the product and

- check receiving of all different shipments at the same time incurring higher transportation costs.

Sending quantity to FBA

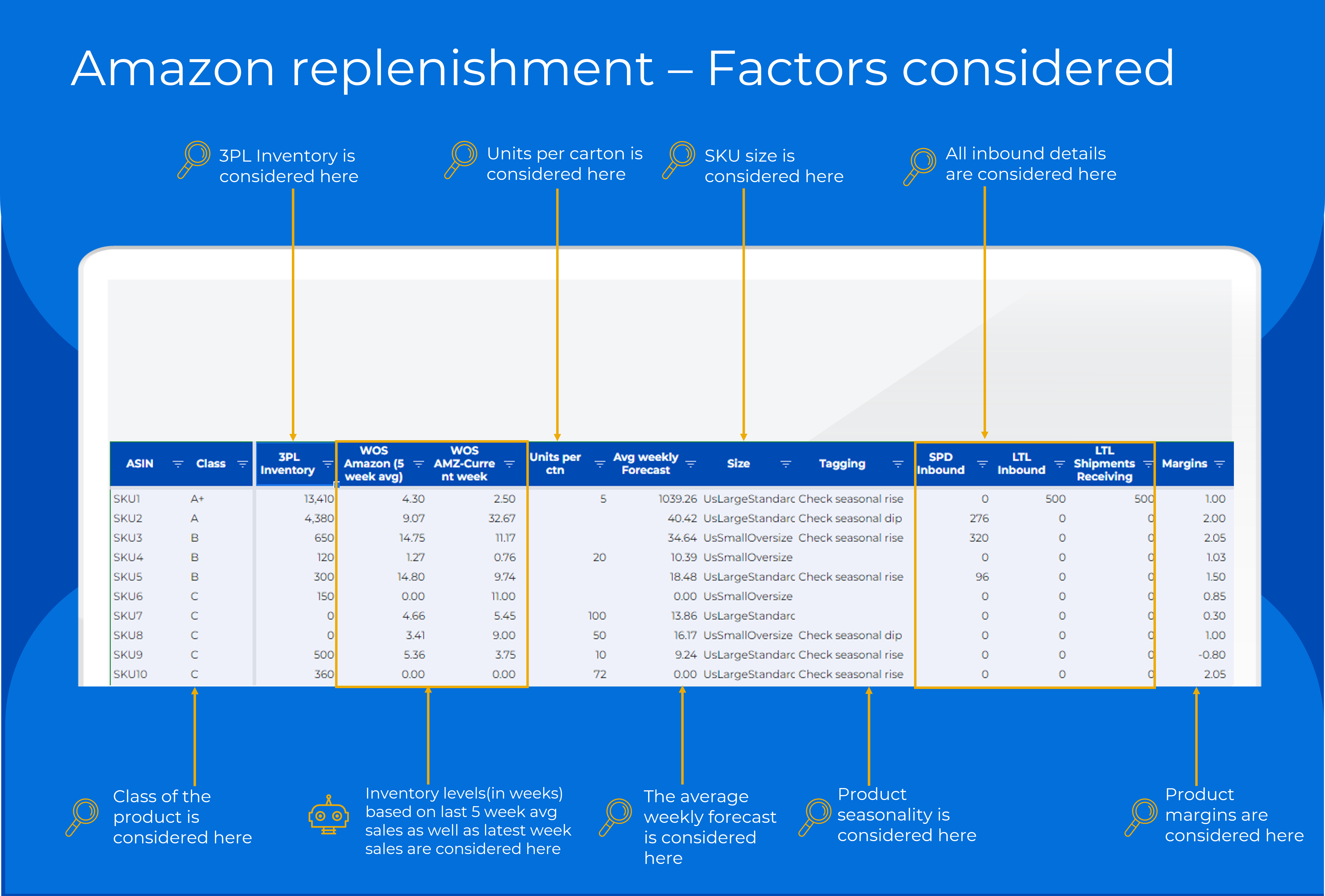

While making replenishment recommendations we already consider quite a few problems which every amazon seller can face. Our recommendations are made considering;

While making replenishment recommendations we already consider quite a few problems which every amazon seller can face. Our recommendations are made considering;

- Seasonality of the products and forecasted sales

- Last 5 week average sales as well as current week sales (to analyze significant jumps as well as drops in orders)

- If a SKU has not been selling for the past 3 months due to out of stock scenarios, we will share recommendations of older sales trend or forecasted sales

- Decrease sales velocity in case there are delay in any incoming shipments

- Optimized transport costs

- Replenishment based on product class

- Addressing minimum stock limits

Deciding transportation method & Optimizing transportation cost

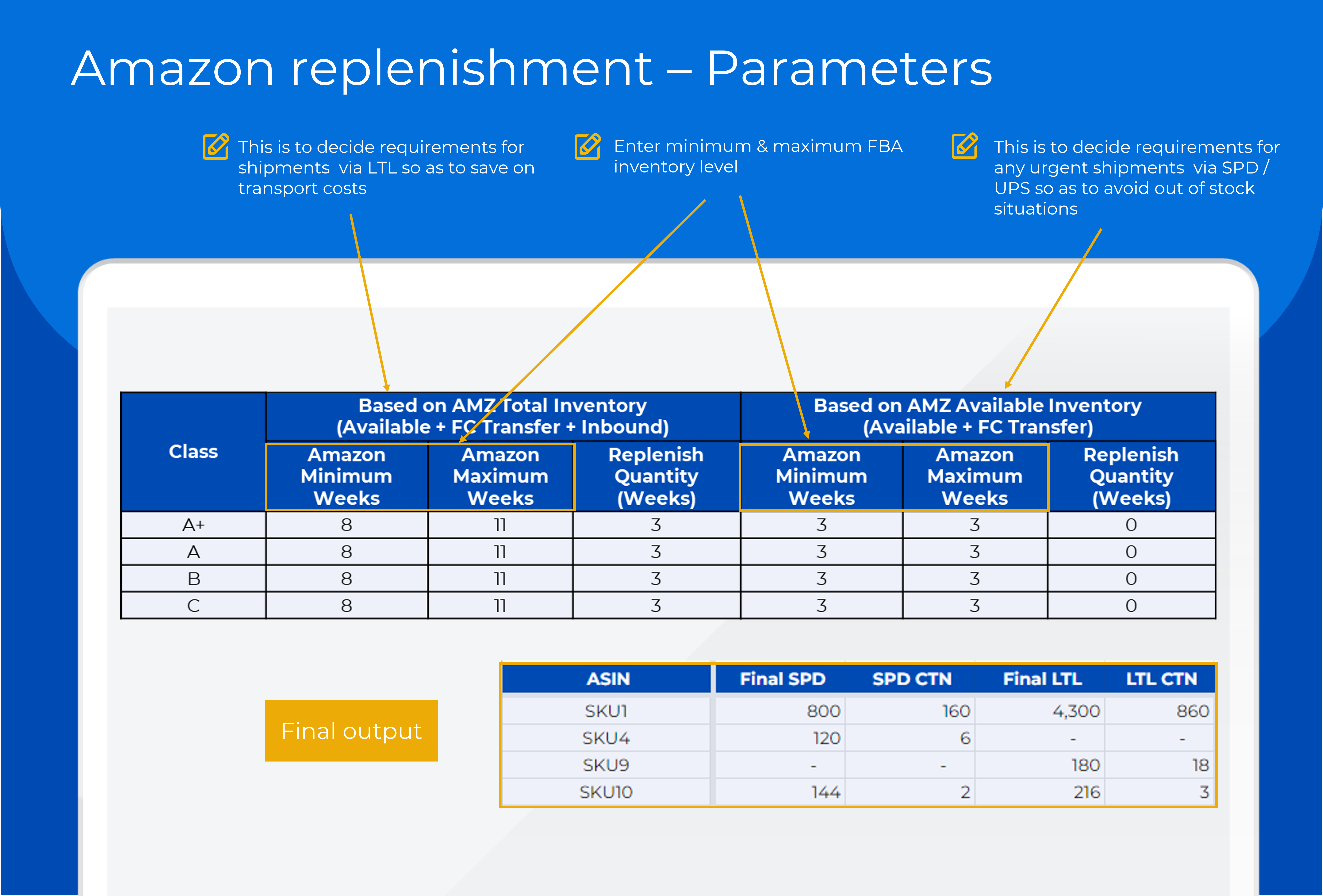

We consider SPD & LTL lead times as well as the safety stock required to calculate the optimum level of stock to be maintained at amazon warehouses. This ensures that transportation cost is saved while replenishing stock at amazon warehouses. While recommending the method of transportation, we consider the urgency of sending the stock to FBA warehouses. In case if the available inventory (Available inventory + FC Inventory) is lower than the minimum stock levels we recommend using SPD mode of transportation after evaluating the following crucial factors

We consider SPD & LTL lead times as well as the safety stock required to calculate the optimum level of stock to be maintained at amazon warehouses. This ensures that transportation cost is saved while replenishing stock at amazon warehouses. While recommending the method of transportation, we consider the urgency of sending the stock to FBA warehouses. In case if the available inventory (Available inventory + FC Inventory) is lower than the minimum stock levels we recommend using SPD mode of transportation after evaluating the following crucial factors

- Margins – If the product has lower margins and in case sending another SPD would further lower the margins, we recommend using LTL mode of transport for replenishment

- Inbound SPDs or LTLs to be received during the week – While considering the available inventory we also take into consideration the shipments which are going to arrive soon into the FBA warehouses and we need not send in any further stock using SPD

- Size of the product – While replenishing stock at Amazon warehouses, at times it might happen that certain products (depending on their sizes) can be shipped either using SPD or LTL mode of transport only

(For e.g. oversized products in certain marketplaces are shipped using SPD only). - SPD and LTL cost are optimized by maintaining optimum inventory levels at Amazon. Also, as mentioned before, while deciding SPD/ LTL we consider whether sending that shipment through SPD would lower the margins and whether it is worth sending using SPD.

Remove & dispose from FBA

Avoid overstocking at Amazon- Overstocking in Amazon leads to higher storage cost and may also lead to utilization of storage limits by non-essential SKUs. Hence, we ensure we replenish SKUs considering the following:

- Category of the product- those SKUs which are more important to the revenue/ profit of the company are preferred over other SKUs for replenishment;

- Where the SKUs are overstocked (more than maximum), we recommend removal from Amazon/ disposal from Amazon. Ofcourse, we first consider the economic relevance of any decision taken.

We can give here the image of parameters of minimum and maximum.

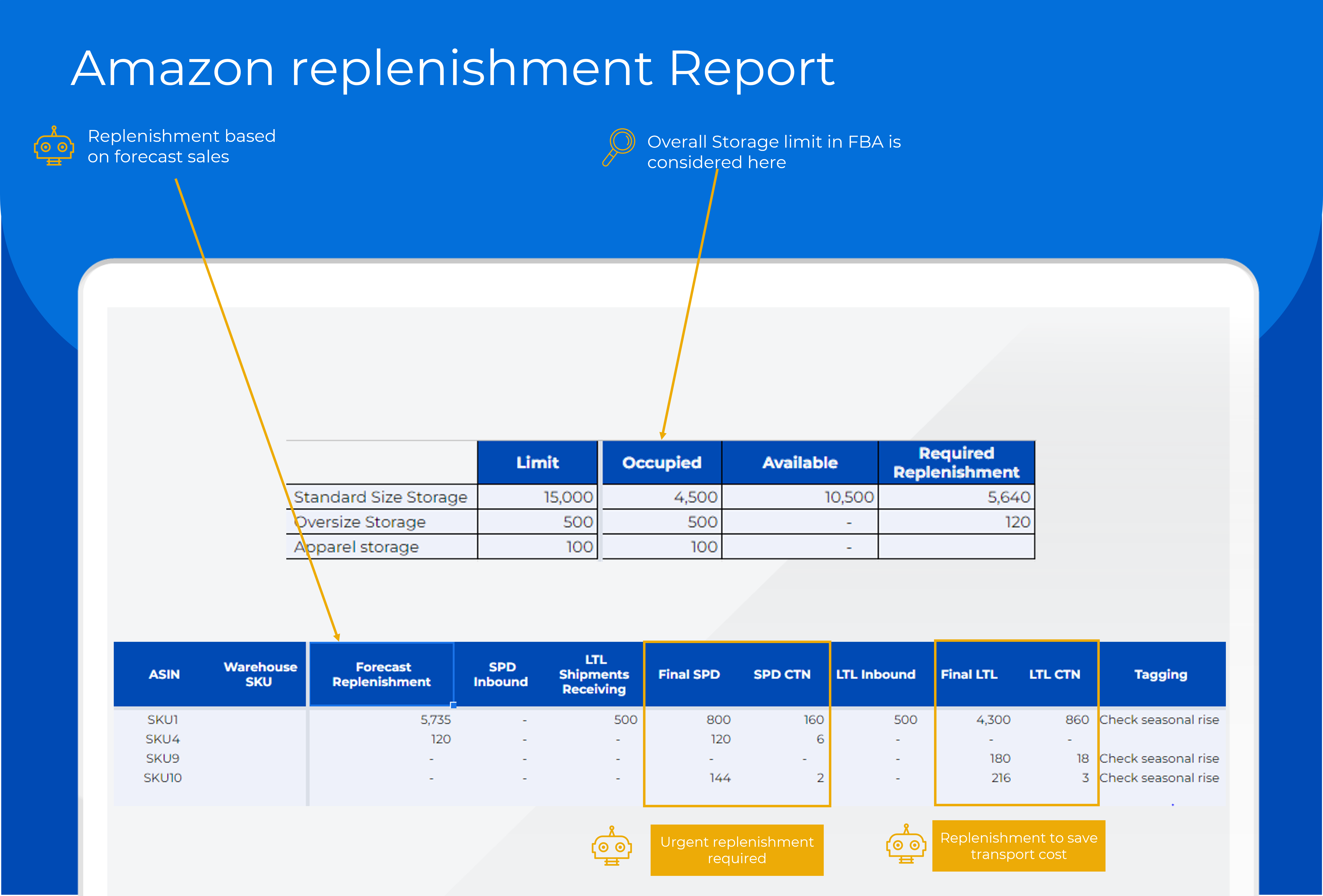

Addressing overall storage limits

Amazon applies storage limits in order to better manage stock at the fulfilment centers. At times, it happens that these limits are lower than what we actually should maintain considering the sales for individual SKUs. In such cases, we need to prioritize which SKUs should be replenished first and which SKUs we need to replenish later as and when the space gets available. In case of lower storage limits, we prioritize SKUs based on various factors like;

- Prioritize according to margins / product class;

- Allocation and distribution of limits by category- oversize, apparels, etc.

- Prioritize according to best selling seasons of the SKUs

- Possibility of postponing replenishment for certain SKUs We also have certain tricks to increase the available storage limits.

FBM decision/ New marketplace decision/ Selling products through NARF/ EFN decision

Amazon Remote Fulfillment with FBA program (in the US) lets the seller sell to customers in Canada and Mexico without having to send inventory to these countries. In the similar way, the European Fulfilment Network (EFN) allows sellers with an Amazon Europe Store account who is also registered for FBA to store their inventory in their local fulfilment center and fulfil orders coming from other European countries as well. We assist in deciding which SKUs can be registered for remote fulfillment and which SKUs should be stored in the warehouse locally considering the more profitable option.

Accurists in Amazon Replenishment & Cost Optimization

Ready to rev up your

Amazon Replenishment & Cost Optimization

We have tackled a variety of problems for E-Commerce companies & Amazon stores.

Let us know how we can help.