Inventory planning & ordering

The most critical task for any e-commerce business is to ensure that all the products are restocked at the right moment so as to avoid any loss of revenue as well as to avoid incurring any high finance costs. We provide restock recommendations to make sure you never run out of stock and there are no revenue losses as well as the profits are optimized.

Low inventory handling cost - minimum storage and finance sot

Avoid loss of profit & stock-out

Accurate and timely recommendations

Developing accurate forecast

It is important to develop accurate forecasts in order to ensure that restock requirements are fulfilled at the right time. While developing forecasts for our clients we take into consideration quite a few factors including:

1. Previous sales history and sales trend analysis;

2. Previous stock outs if any,

3. Any planned deals,

4. Performance during specific events like Black Friday, Prime Day, etc.

5. Seasonal fluctuations We also consider the cost of overordering any SKUs because of the high MOQs vs what can be the expected loss of revenue because of running out of stock.

Once forecasts are created, we monitor those on a periodic basis to analyze if the forecasts are in line with the actual numbers. This saves the transport cost as well as the storage costs since restock is done at the right time and in required quantities.

Deciding forecasting period

Forecasting is generally done for a span of 8-12 months depending on the lead times and other factors affecting the business. Once the forecasting period is finalized, forecasts created are revisited every month after comparing with the actual sales and forecast is created for the next month.

Restock frequency

We can recommend restock frequency according to the Inventory turnover for each SKU or vendor/ brand. You can set the restock frequency monthly and we can decide monthly how much to restock with weekly/ daily reporting of understocked SKUs.

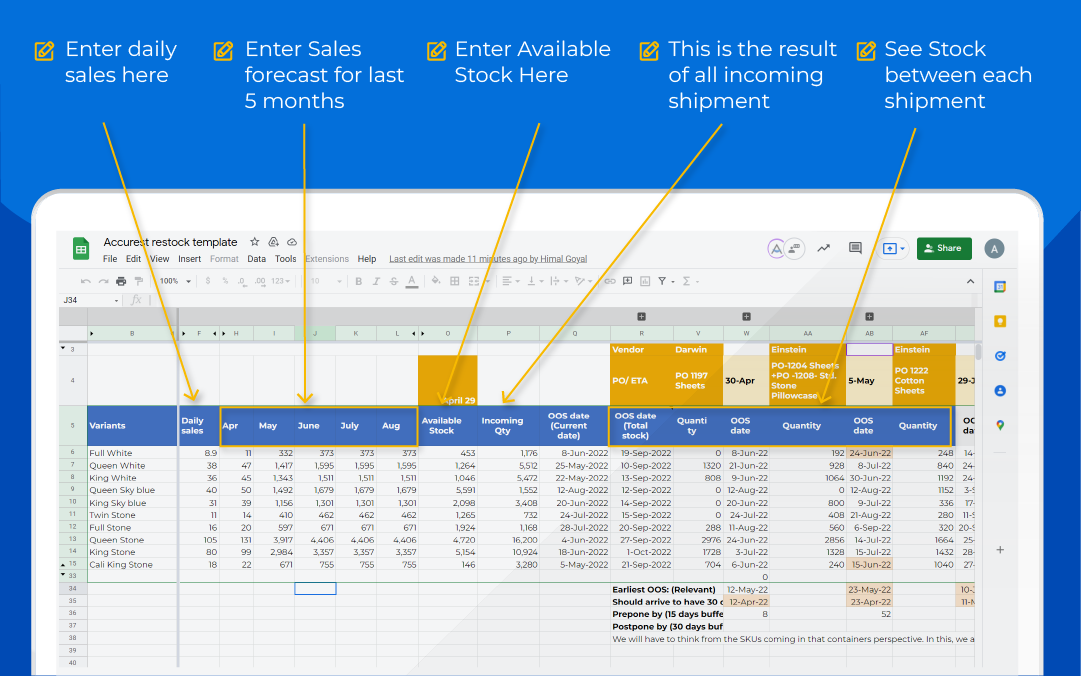

Restock calculation

Our restock calculations are based on various factors and provide quick and better decisions to the seller. The recommendations are made keeping in mind that significant time is saved by the seller managing a large number of SKUs across different marketplaces.

Our restock calculations are based on various factors and provide quick and better decisions to the seller. The recommendations are made keeping in mind that significant time is saved by the seller managing a large number of SKUs across different marketplaces.

Container optimization- 20 feet or 40 feet

Container optimization helps in saving shipping costs as space gets fully utilized. We have developed tools which help you do accurate calculations based on your sales forecast for each SKU like:

- Calculating the CBM of the total order while ordering help in determining the type and number of containers while ordering.

- Orders each SKU such that all the SKUs go out of stock at the same time and we don’t order a lot of a particular SKU;

- Increase the Inventory turnover by ensuring the number of orders placed are less;

Add specific Restock criteria's (Changes to restock)

Aside from product specific factors like MOQ, product dimensions, many of the factors for ordering are vendor specific too. You can setup specific parameters for restock like at a vendor/ port level or even overall level:

- Minimum quantity for each vendor;

- Minimum CBM per vendor;

- Minimum CBM per port

- Order till specific date;

- More safety for specific vendor or specifc port or specific products;

Once the restock requirement is finalised as per above, you can review the list and make changes to order for each SKU.

SKU reshuffling between containers

We also allow you to easily update the container quantity and PO quantity based on issues in production of a particular SKU or urgency of a particular SKU compared to other SKUs ordered from the vendor.

Preponement/ Postponement decisions

We also share recommendations based your forecast and ETA of the shipments coming to either:

- If you have overstock, we recommend to postpone the shipment on real time basis to avoid blockage of funds and storage cost;

- If you are understocked, we recommend to prepone the shipment by requesting the vendor to push the ship date. We also share air-ship recommendations based on the stock levels to avoid out any stock scenarios;

Accurists in Inventory planning & ordering

Ready to rev up your

Inventory planning & ordering

We have tackled a variety of problems for E-Commerce companies & Amazon stores.

Let us know how we can help.