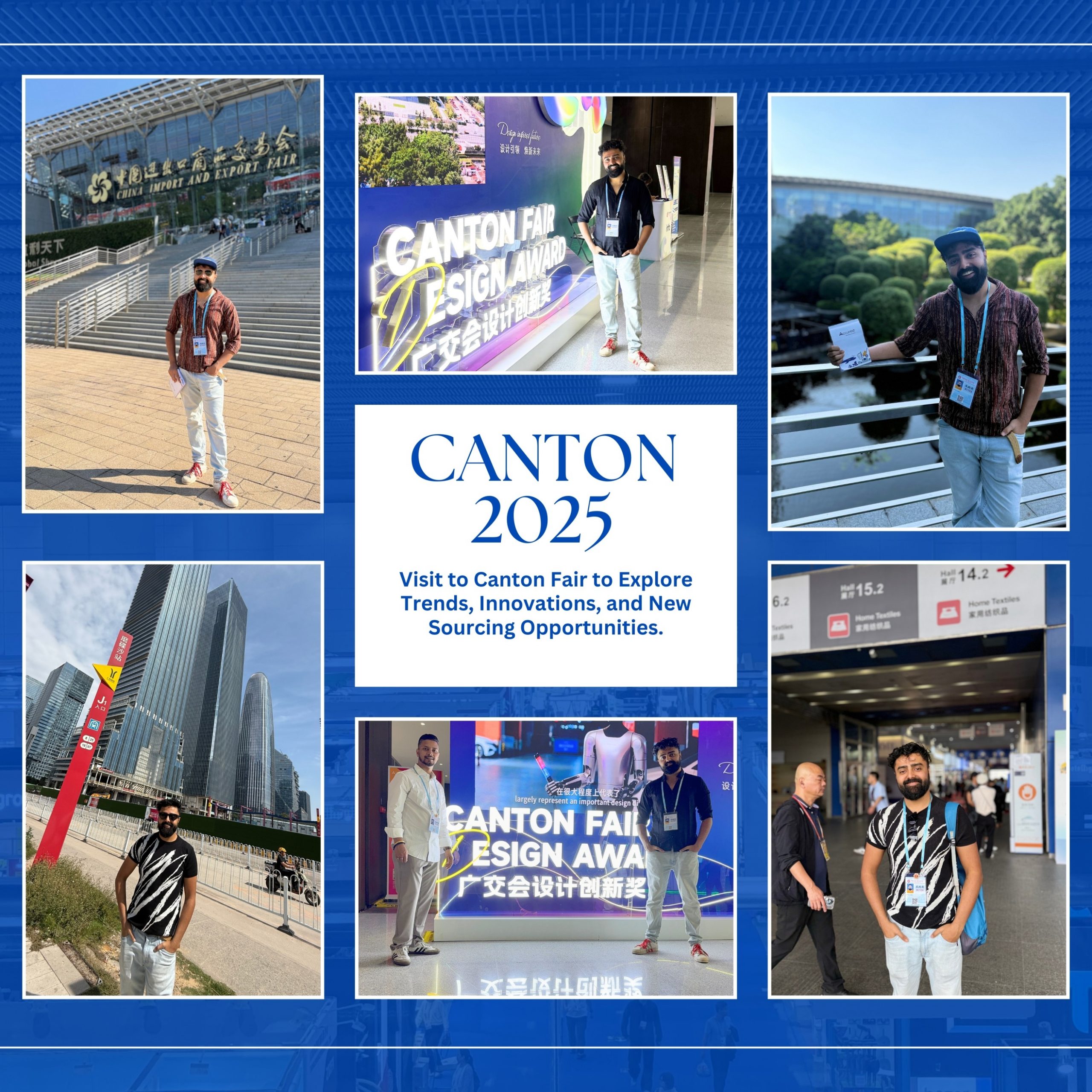

Visiting the Canton Fair this year was more than a routine sourcing trip — it offered a clear view of how global supply chains are shifting and what today’s businesses truly need.

Across Phase 2 and Phase 3, the focus was on identifying practical solutions that directly support our clients’ sourcing challenges.

A key priority was MOQ optimisation. As many of our clients work with growing yet variable volumes, high MOQs often restrict flexibility. At the fair, I connected with vendors who understood this friction and offered far more adaptable MOQ structures. This enables our clients to source smarter, avoid unnecessary inventory buildup, and scale order sizes based on actual demand. This means our clients can now source smarter, avoid overstocking, and still manage their costs effectively.

Another strong focus was on payment terms and lead time. The conversations with suppliers were promising — many were open to better payment cycles, faster lead times, and more transparent production timelines

Even small improvements in these two areas can dramatically improve the overall health of a client’s supply chain.

We also explored New Product Introduction (NPI) options within categories that the vendors already specialise in. This helps sustain quality, reduce sampling risks, and speed up development cycles. We further evaluated NPI options that align with our clients’ existing assortments and resonate with their target customers, ensuring relevance and commercial sense.

By combining insights from both Phase 2 and Phase 3 of the Canton Fair, we’ve strengthened our sourcing strategy — enabling a broader, more resilient, and cost-efficient product network for our clients. Overall, the Canton Fair gave us stronger vendor partnerships and shifted toward flexible, transparent, and faster manufacturing, which directly strengthens sourcing efficiency for clients

Key Takeaway from the Canton Fair

Sourcing is no longer just about buying products — it’s about building a supply chain that is flexible, capital efficient & incorporates smarter decision making. Aligned to reduce inventory drag, improve terms, and speed up the whole chain